Our Services

Services OfferedINLINE INSPECTION & PIGGING

Across the globe, Inline inspection (ILI) is the preferred method for detecting and measuring a wide range of faults in operational pipelines. We operate a comprehensive range of ILI technologies and tool sizes to suit the needs of onshore and offshore, gas and liquid pipeline operators worldwide. Our ILI services are fully supported by specialised reporting and analysis software and are designed to locate and measure a wide variety of pipeline faults.

In addition to ILI tools, we provide a wide variety of pigging solutions for a range of applications, including pipeline bore-proving / gauging, pipeline cleaning, and profiling for the safe passage of specific ILI tools.

Our ILI services include both conventionally-driven and bi-directional tools and are based on:

- Axial-Field Magnetic Flux Leakage (MFL)

- Transverse-Field Magnetic Flux Leakage (MFL)

- Ultrasonic (UT)

- Caliper

- Inertial Measurement Unit (IMU) / XYZ

- Deformation

INSPECTION SERVICES

Inspipe operates a range of inspection and quality assurance services for pipelines and other engineering structures. We operate worldwide with extensive experiences of the energy sector, including the oil, gas and renewable energy industries. Other areas within our experiences include ship building, dry dock ships and rigs.

All services are delivered globally by a team of highly qualified inspectors. NDT methods can be combined to provide an integrated analysis of a structure’s integrity based on multiple-technology evaluations.

As a part of our development program, we support our services with advanced technologies such as Artificial Intelligence and Automation. This delivers many benefits for clients, including enhanced economy, better repeatability and higher quality results.

METHODS

- Inspection Engineering

- Remote Inspections

- clcleraAsset Integrity Services

- Repair and Maintenance Solutions

Rope Access Services

- Magnetic Particle Inspection (MPI)

- Dye Penetrant Inspection (DPI)

- Eddy Current Inspection (EC)

- Ultrasonic Testing (UT)

- Radiography (RAD)

Non-Destructive Testing (NDT) Services

- Pulsed Eddy Current (PEC)

- Computed (CR) and Digital Radiography (DR)

- Remote Visual Inspection Systems (UAV, ROV)

- Time of Flight Diffraction (ToFD)

- Phased Array Ultrasonic Testing (PAUT)

Advanced Non-Destructive Testing (NDT)

SERVICES

- Third Party Inspection

- Ship Dry-Docking inspection

- Project Expediting

- Site Surveillance

- Site QC Supervision / Management

- FAT & Final Inspection

QA/QC Inspections

- ITP & Quality Plans Development

- Specification/Procedure Development

- Laboratory Tests witnessing

Welding & Coating Inspections

- Welding and Fabrication Inspection

- Coating & Painting Inspection

- Specification/Procedure Development

- Technical Assistance & Consulting

- Corrosion, Coatings & Linings Testing

- Procedure Qualification

- Material EN 10204-3.2

Welding & Coating Inspections

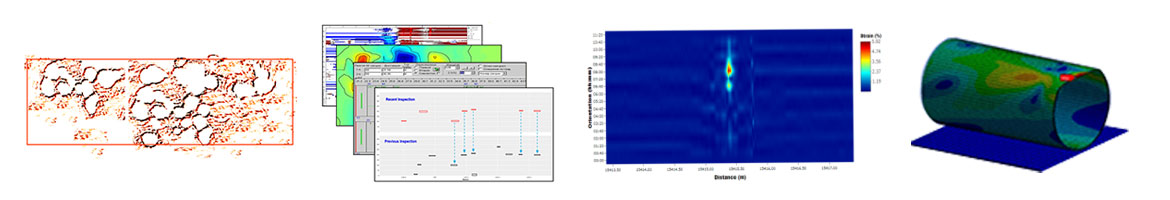

PIPELINE INTEGRITY SERVICES

Good integrity management means end-to-end regulatory compliance and this demand drives our full range of integrity services. Our credentials are acknowledged worldwide, as are our highly qualified and experienced people, our enviable track record and exceptional technical capabilities..

Inspipe Integrity delivers a full range of integrity assessments to support pipeline operators, including:

- Detailed FFS assessment to characterise and assess the impact of threats onimmediate and future integrity

Fitness for Service (FFS)

- Assessment comparing 2 or more sets of ILI data

- Corrosion growth rates quantified along the pipeline

- Box matching / signal comparison, complemented by segmentation to avoid conservatism

ILI Run Comparison & Corrosion Growth

- Quantification of dent strains from geometry tool data, laser scans or satellite ground movement surveys

Dent Strain Assessments

- Strain levels calculated from IMU/XYZ data in locations of possible pipe movement

Bending Strain Analysis

- Specialised assessments using Finite Element Analysis (FEA)

Level 3 Assessments using FEA

Life Extension / Remaining Life Assessments

Development of Repair Plans and Procedures

Crack Assessments

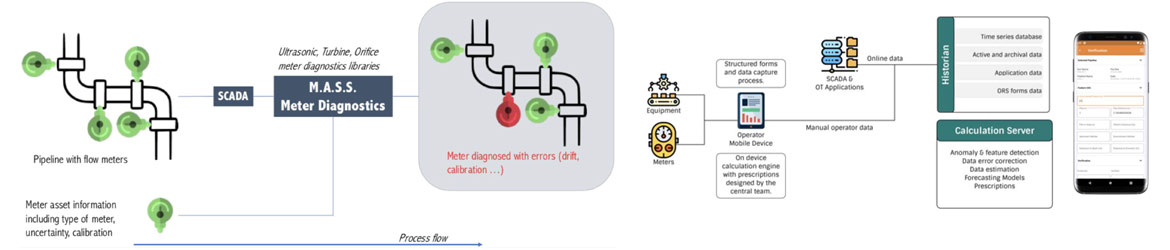

IM SOFTWARE SYSTEMS

The integrity management of pipelines and other engineering assets is a highly complex process involving vast amounts of data. Since integrity management is necessay in every part of a client’s business operations, proven software solutions must be available for areas as diverse as structural integrity, product storage, metering and SCADA.

Inspipe installs, commissions and maintains client-based and cloud-based software systems to support key processes, including:

- Integrity Control

- Threat Assessment and Threat Management

- Risk Management

- High Consequence Area (HCA) Identification

- Inspection Data Optimization

- Data Acquisition & Monitoring

- Data Uploads, Data Alignment, Integration and Verification

- Data Silo Merging

- Operator Data Systems, including Field Operatives Data

- Metering & Product Reconciliation

- SCADA & IoT Software

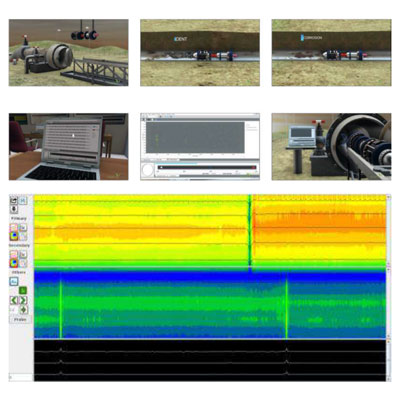

NEW TECHNOLOGY DEVELOPMENT

Our work on new technologies is wide-ranging and includes:

- New Pipeline Materials, Construction and Threat Monitoring

- Technology Convergence, e.g. sensing, data processing, communications, IoT

- Artificial Intelligence & Robotics

- Embedded Systems / Automation

- Smart Objects & Systems

- Remote Sensing, e.g. Multi-Spectral Satellite Surveys

- Augmented reality / VR

SATELLITE SURVEYS & MONITORING

Inspipe delivers Satellite Remote Sensing technology and Geospatial Analytics to support the integrity management of pipelines and other assets, and to develop business and governance solutions. Data from space borne sensors are used to measure changes and activity in the microwave, infrared and visible spectrums, allowing the observation of key phenomena that could otherwise be missed by conventional methods. From monitoring hydrocarbon pipelines, water resources and critical infrastructure, we can provide valuable insights to enable businesses and governments to make better informed decisions.

- Satellite Remote Sensing technology and Geospatial Analytics

- Measurement of changes and activity in microwave, IR and visible spectrums

- Monitoring of hydrocarbon pipelines, water resources and critical infrastructure

- Provision of valuable information and vital services for better informed decisions

In the case of pipelines, Active and Passive Satellite Remote Sensing is based on Infrared (IR), Radiometry, Microwave, Visual, Laser and Synthetic Aperture Radar (SAR) methods. These systems are used in a wide range of measurements.

- Geotechnical Surveys

- Leak Detection

- HCA Classification

- Right Of Way (ROW) Monitoring

- Land Use

- Subsidence and Ground Movement

- Slope

- Elevation

- Topography

- Soils

- Drainage

- Soil Moisture